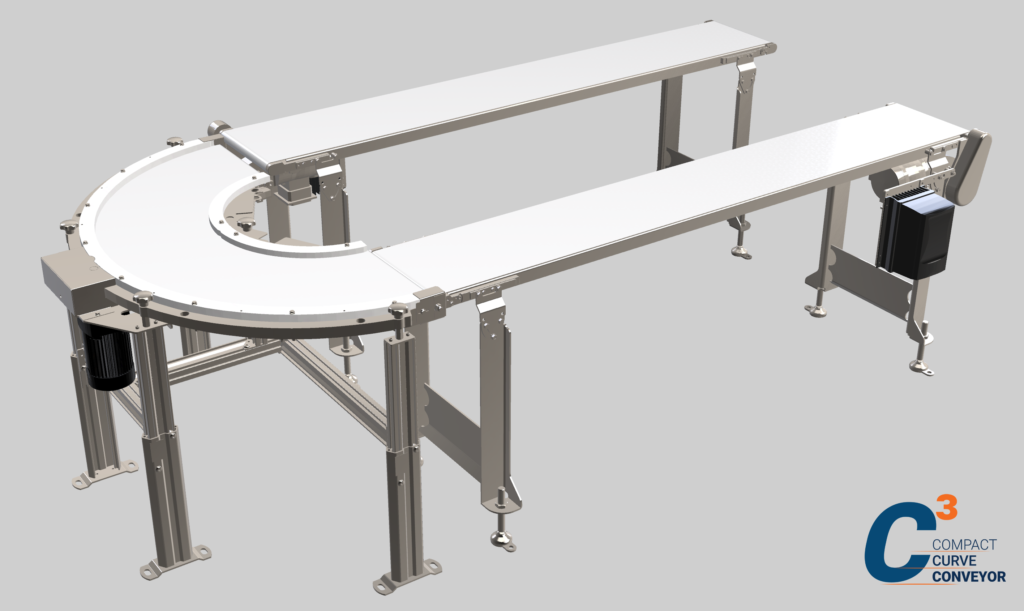

The C3 Compact Curve Conveyor can be utilized in a bakery production facility needing to handle unpackaged and packaged bakery goods in different stages of the production cycle.

The Challenge

In a bakery facility with limited production space, adding new lines or processes for additional products is almost unmanageable. A bakery looking to add a new delicate product, such as bagels, needs smooth transport and a tight transfer to maintain product quality. In order to move this product to the next stage in the operation they need the product to keep the leading edge and be unharmed during transport.

The Consultation

Dorner’s engineering team uses the initial consultation with customers to learn more about the bakery needs and understand the exact requirements of the production line. Our team works to understand key pain points for a customer’s operation in order to develop a system design that solves those problems. In bakery and confectionery operations we often see:

- Floor Plan

- A bakery may need to be able to move unpackaged baked goods to the next step in the operation. Because of limited floorspace they need to utilize the space next to the straight conveyor to send the product in a different direction.

- Transfers

- Because bakery items are so delicate, product movement needs to be seamless and secure. Transferring from a proposed curve conveyor to the straight sanitary conveyors is critical and the transfer must be tight from one conveyor to the next.

- Leading Edge

- Products need to be orientated correctly for the next step in the operation, so the leading edge must be maintained despite the product moving directions throughout the facility

- BISSC Certification

- BISSC certification in all automation in a bakery plant is critical to uphold the sanitary standards that this bakery manufacturer requires.

The Solution

Dorner’s engineering team takes all aspects of the initial consultation and develops a solution to meet all of the demands that the manufacturer would require. Considering the pain points above, C3 offers the best solution to meet their needs.

- Floor Plan

- C3 provides 3 different angles (45°, 90°, and 180°) options for moving product in a different direction based on the requirements of the application. For this application the 180° option can be used to move the product back in the direction that it came from, maximizing the available production floor space.

- Transfers

- With the C3’s 25 mm small pulley, transferring delicate bakery products seamlessly from the C3 to another sanitary conveyor is simple and reliable. Attaching Dorner’s BISCC-approved AquaGard LP to the C3 via brackets ensures a smooth transfer from the belted curved conveyor to a straight production line.

- Leading Edge

- Because these products need to be orientated in the correct way for the next step in the operation it is crucial to utilize the C3’s 180° to keep the leading edge of the product and maintain consistent laning.

- BISSC Certification

- Dorner’s standard for sanitation in food production is apparent with the C3 Compact Curve Conveyor with its BISSC certification and stainless-steel construction. This conveyor is designed for wipe down and blow off cleaning which is perfect for this bakery application.